Description

Process of glass molybdenum electrode: isotactic pressing – sintering with medium frequency furnace – forging to various shapes – turning, rolling, planning and milling to finished parts. We offer different kinds of moly electrodes as your requirements.

We have produced electrode for years, and spare no effort to the improvement of the electrodes performance. With the excellent characteristics of high strength and resistant to oxidation under high temperature, long life and good corrosion resistance, these high pure electrodes are widely used in many fields such as daily-use and optical glass, insulation material and glass fiber.

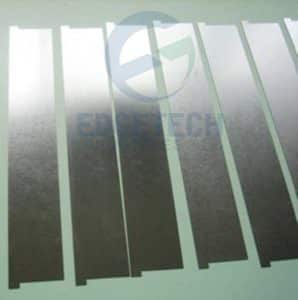

Moly Electrode

Specification for Moly electrode

| Product | Molybdenum electrode & cathode |

|---|---|

| Appearance | Silver gray metallic luster |

| Density | >9.8g/cc |

| Purity | Mo≥99.95% |

| Dimension | 14~20mm x 14~20mm x L, per drawings |

Application for Moly electrodes

-Used as electro-heat equipment of the glass fiber kiln.

-Plate electrode (3~25mm x 50~500mm x L L<800mm) can be used as various kinds of heating equipment of glass fiber kiln, liquid-flow hole panel, etc.

-Rod Electrode (20~100mm diameter x L) is mainly used as the furnace, electric boosting glass kiln electrode, etc.

Molybdenum is a with symbol Mo and the atomic number 42. It’s an outstanding material that can meet the most exacting requirements due to the unique mechanical and chemical properties. Molybdenum possesses a very high melting point, a low coefficient of thermal expansion and a high level of thermal conductivity, it is employed in many different industries.

Product information:

Customer information: