Description

Ion implantation is an important process in the manufacture of semiconductors. The most important part of an implant system is the beam path. Here, the ions are generated, concentrated, accelerated, and targeted towards the wafer. Our parts are made from molybdenum and tungsten due to these materials ideal combination of corrosion resistance, strength, and high thermal conductivity.

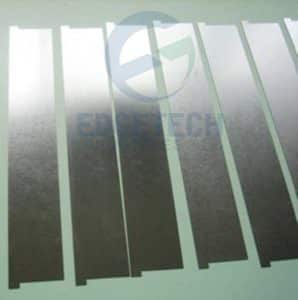

Molybdenum Parts

& Parts Properties

-High Melting point

-Outstanding creep resistance

-Excellent corrosion resistance

-Good electrical and thermal conductivity

-Outstanding purity

Our products for the semiconductor industry:

-Chambers (tungsten, molybdenum and alloys)

-Filaments (tungsten and tungsten alloys)

-Arc slits (tungsten, molybdenum and alloys)

-Holders (tungsten, molybdenum and alloys)

-Cathodes (tungsten, molybdenum and alloys)

-Spare parts (tungsten, molybdenum and alloys, ceramics, steel)

About Molybdenum

Molybdenum is used for its extremely high melting point and relative flexibility. Molybdenum has a melting point of 2,623 °C. Molybdenum has a high elastic modulus, and only tungsten and tantalum have higher melting points. Typical applications for Molybdenum are crucibles, evaporation boats, propulsion components, x-ray tube, lighting industry, glass melting electrodes, high temperature furnaces, sputtering targets, heat sinks, heating elements, electrodes, stirrers, orifice plates, support members, mandrels, shields, sintering trays, filaments, furnace windings, thermocouple sheathes, nose cones, nozzles, jet tabs, contacts, brazing fixtures, boring bars, tools, heat radiation shields, cathodes, and aircraft and missile parts and nuclear energy applications where high temperature resistance is crucial.

Contact us at for inquiries on ion implantation components made by tungsten and molybdenum.

Product information:

Customer information: