Description

Tungsten based composites are strong refractory metal materials manufactured by a strictly controlled process involving pressing, sintering and infiltrating with copper or silver. They are highly resistant to heat, electric arc, wear and deformation at high temperature welding, flash butt and spot welding. They also have excellent electrical and thermal conductivity. The properties of Tungsten composites are related to the copper/silver-to-Tungsten ratio.

If the content improves, the electric arc and wear resistance will increase while the thermal and electrical conductivity, on the contrary, reduce. Due to their unique properties, Tungsten based composites are widely used where the combination of good electrical and/or thermal conductivity and low thermal deformation is necessary, for example:

AgW75, this composite is one of the high refractory content Tungsten silver materials made by press-sinter-infiltration and normally a high resistance to arc erosion. It is generally used as arcing contacts in large air and oil circuit breakers, line disconnects, re-closures, and in high current switches and contacts. Contact resistance is low enough to protect the higher conductivity current carrying contacts from arc damage. Its resistance to welding makes it a good shorting contact for bi-metal protection in circuit breakers.

AgW70 and AgW50, these composites have more silver than AgW75, which provides higher conductivity and a lower contact resistance. They are used extensively in a large variety of circuit breakers. In this application, a single pair of contacts provides the dual function of carrying the current without overheating, and interrupting the current without excessive arc erosion. They are also used in high current contacts where resistance to contact welding and arc erosion are required. In a variety of DC applications, they offer resistance to metal transfer.

AgW50, this composite has the highest silver content of the press-sinter-repress Tungsten silver materials. It exhibits good resistance to contact welding and is used for current carrying contacts in power circuit breakers that encounter high momentary currents.

Properties for our tungsten silver products

| Composites | Nominal composition (% Weight) | Density (g/cm3, ≥) | Electrical resistivity (20ºC, μΩ.cm, ≤) | Electrical conductivity (IACS%, ≥) |

|---|---|---|---|---|

| W50Ag | 50W, 50Ag | 13.15 | 3.0 | 57 |

| W55Ag | 55W, 45Ag | 13.35 | 3.2 | 54 |

| W60Ag | 60W, 40Ag | 14.00 | 3.4 | 51 |

| W65Ag | 65W, 35Ag | 14.50 | 3.6 | 48 |

| W70Ag | 70W, 30Ag | 14.90 | 3.8 | 45 |

| W75Ag | 75W, 25Ag | 15.40 | 4.2 | 41 |

| W80Ag | 80W, 20Ag | 16.10 | 4.6 | 37 |

Specifications for our tungsten silver products

| Type | Length (mm) | Width (mm) | Thickness (mm) | Diameter (mm) |

|---|---|---|---|---|

| Rod | 2 ~ 300 | — | — | 2 ~ 320 |

| Plate | 10 ~ 300 | 10 ~ 300 | 2 ~ 200 | — |

| Other parts | Tungsten silver cube, ring, block, electrode and other customized parts are available per request | |||

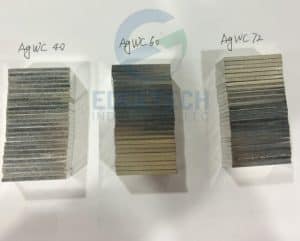

Tungsten Carbide Silver

Tungsten carbide silver composites are with a higher hardness but lower electrical conductivity than the silver Tungsten grades. They are suitable for air switching operations where a high arc and mechanical wear resistance are required. They are used in DC switch-gear, miniature circuit breakers a heavy duty relays. We can supply tungsten carbide silver with the same tungsten content as tungsten silver materials.

Product information:

Customer information: