Description

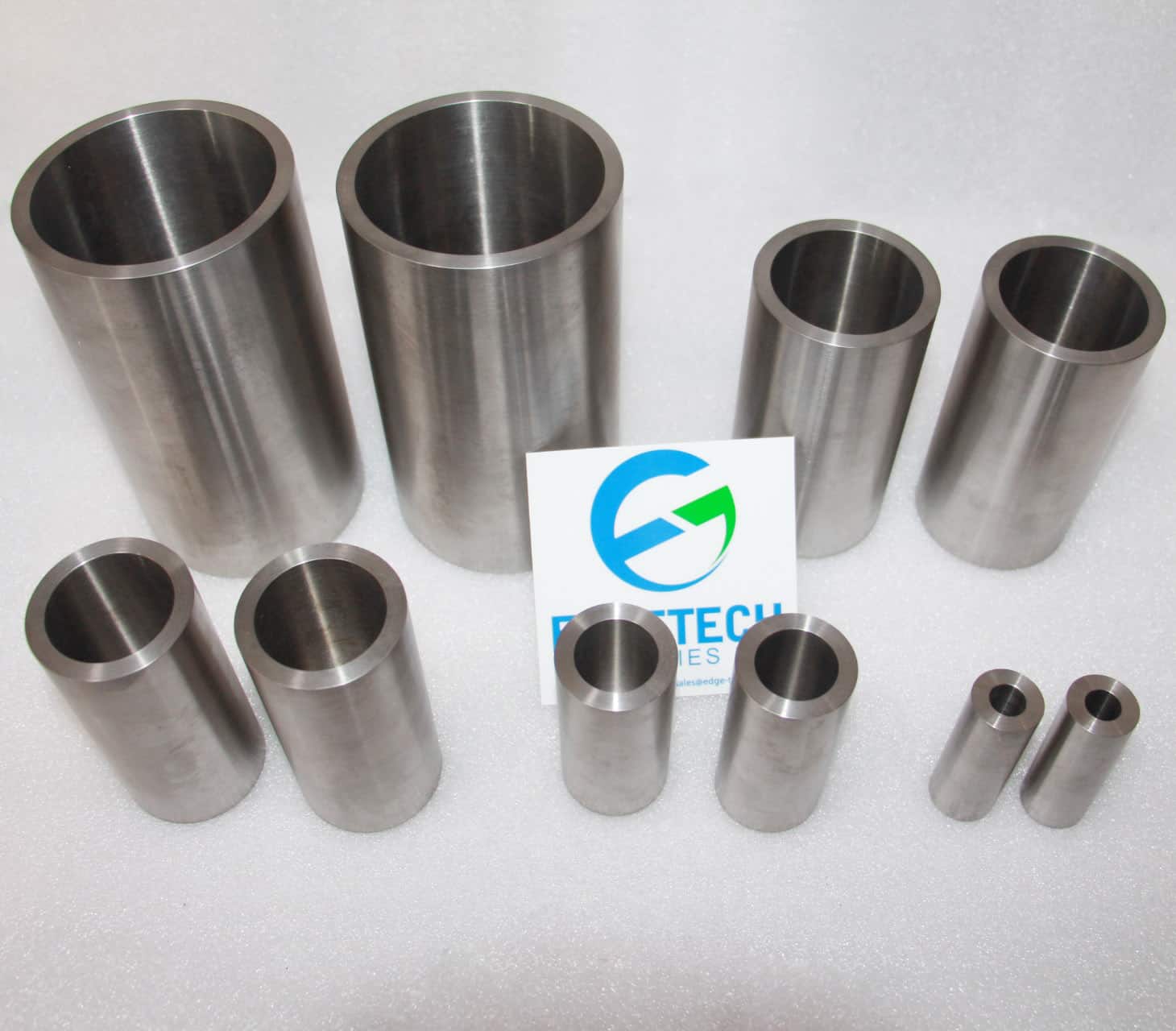

High density tungsten alloys provide a unique combination of density, mechanical strength, machinability, corrosion resistance, and economy. These versatile materials provide distinct advantages when compared to traditional high-density materials such as lead or uranium. Incredible strength, consistent durability and long-lasting value—our high density tungsten alloys (tungsten heavy alloy) are the perfect choice for radiation shielding, weights and counterbalances, boring bars and grinding quills, crankshaft balancing, rotating inertia members, ordnance components, and high-temperature tooling applications.

W-Ni-Fe alloys and W-Ni-Cu alloys (with tungsten content 90%~97%) are regular tungsten heavy alloys with high density. We offer a variety of high density alloys, available in bars, plates, sheets, foil, rods. We also have extensive machining capabilities, allowing us to provide weights in standard sizes or custom products finished to your required specifications. We also provide tungsten lanthanum alloy products in shaped and machined forms.

Properties of tungsten heavy alloys:

- High density (17-18.5g/cm3)

- High melting point

- Wear resistance

- High tensile strength

- Good elongation capacity

- Low vapor pressure

- Excellent thermal stability and

- High radiation absorption capacity

- Slightly Magnetic

Due to these advantages they are widely used in various fields including the sports, industry and medicine, etc. The most common high density tungsten alloys are Tungsten Nickel Iron Alloy (W-Ni-Fe Alloy) and Tungsten Nickel Copper Alloy (W-Ni-Cu Alloy).

Physical and mechanical properties of Tungsten Heavy Alloys:

| Alloy Type (wt%) | 90W-7Ni-3Fe | 90W-6Ni-4Cu | 93W-5Ni-2Fe | 93W-4Ni-3Cu | 95W-3.5Ni-1.5Fe | 95W-3.5Ni-1.5Cu | 97W-2.1Ni-0.9Fe |

| MIL-T-21014 | Class 1 | Class 1 | — | — | Class 3 | Class 3 | Class 4 |

| SAE-AMS-T-21014 | Class 1 | Class 1 | — | — | Class 3 | Class 3 | Class 4 |

| ASTM B777-87 | Class 1 | Class 1 | — | — | Class 3 | Class 3 | Class 4 |

| Typical Density (g/cc) |

17.1 | 17.0 | 17.6 | 17.6 | 18 | 18 | 18.5 |

| Typical Hardness RC | 25 | 24 | 26 | 26 | 27 | 27 | 28 |

| Yield Strength (Min, Mpa) |

650~850 | 550~750 | 650~850 | 550~750 | 600~750 | 500~700 | 620~670 |

| Elongation % | 20~25 | 8~15 | 15~20 | 5~10 | 8~13 | 3~5 | 2~5 |

Dimensions of

| Product | Item Code | Length (mm) | Width (mm) | Thickness (mm) | Diameter (mm) |

| Rod | HM74-WR | 2 ~ 600 | — | — | 2 ~ 320 |

| Ball | HM74-WB | — | — | — | 1.5 ~ 200 |

| Plate | HM74-WP | 10 ~ 600 | 10 ~ 300 | 2 ~ 200 | — |

| Other types | HM74-WX | Cube, ring, block and other customized shaped products | |||

Application related tungsten alloy products:

–

–

–

–

–

–

Edgetech Industries LLC provides different kinds of tungsten heavy alloy products, we also manufacture them according to clients’ specifications. Please send us drawings for tailor-made tungsten alloys to .

Product information:

Customer information: