Description

Pure Molybdenum fasteners (molybdenum nuts, molybdenum washers, molybdenum screws, molybdenum bolts and molybdenum threaded rods) have excellent heat resistance. With their high melting point, molybdenum fastener is useful for heat resistant devices such as sputtering equipment and high temperature furnaces. Metric molybdenum fasteners and ANSI standard molybdenum fasteners are available. and Mo-La alloy can also be made to molybdenum alloy fasteners.

We now have the capacity of making micro molybdenum nuts and molybdenum screws as M1.5 and M2.

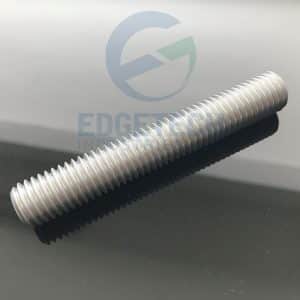

Molybdenum Threaded Rods, Bolts

Molybdenum Bolt

Molybdenum threaded rods (Molybdenum bolts) are produced for high temperature vacuum environments. They can be cut and finished off to desired lengths. In many cases, cut pieces can be coupled with washers and nuts to emulate a screw.

Molybdenum Screws

Molybdenum Screws

Molybdenum screws are produced for high temperature vacuum environments. We produce three head types (fillister, pan & flat) in both ANSI and metric sizes. We stock these refractory screws in standard lengths, but can also produce custom lengths and custom features. Please take note of the sketch provided for screw specs.

Molybdenum Nuts

Molybdenum Nuts

nuts are available in both inch and metric sizing. Our regular molybdenum nut is the hex nut.

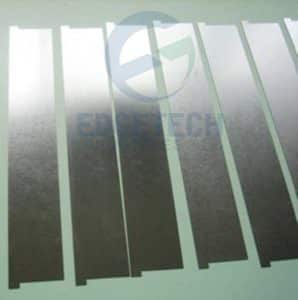

Molybdenum Washer

Molybdenum Washer

Molybdenum washers are available in both inch and metric sizes. Washers help to distribute the load of a threaded fastener. We can produce custom molybdenum washer.

Packaging of Molybdenum fasteners (Nuts, Washers, Screws and Threaded rods)?

Our molybdenum fasteners are wrapped in foam and packaged in crate?or?carton to ensure safe storage and transportation.

ANSI Screw Threads Size chart for our molybdenum fasteners?.