Description

Applications of tantalum ingot

1. In laboratory equipment.

2. A substitute for platinum.

3. Manufacturing superalloys and electron-beam melting.

4. Can be used in metallurgical, machinery processing, glass, and ceramic industries.

5. As a superalloy additive in nickel-based alloys.

6. Deposition materials as sputtering targets.

Tantalum rod

is especially resistant to chemicals at temperatures below 300F and can only be dissolved with hydrofluouric acid. Tantalum has the fourth highest melting point of all metals and is able to form extremely thin and protective oxide layers for high-quality capacitors.

We also provide tailor-made tantalum alloy ingot, such as tantalum tungsten alloy, tantalum niobium alloy.

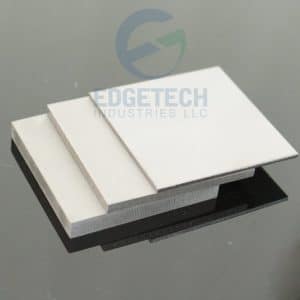

Specifications for our tantalum ingot and tantalum tungsten alloy ingots

Material: R05200, R05400, R05252(Ta-2.5W), R05255(Ta-10W)

Size: Diameter: φ60mm-190mm, Length: 50-1600mm

Standard: As per ASTM B364

and cylinders are with smaller diameters.

Tantalum and Tantalum Alloys

R05200, unalloyed tantalum, electron-beam furnace or vacuum-arc melt, or both

R05400, unalloyed tantalum, powder-metallurgy consolidation.

R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace or vacuum-arc melt, or both.

R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Packing information for our Tantalum Ingot: We use wooden crates for packing our tantalum, this can protect the products during transportation and handling.

We can also provide custom tantalum cylinder and machined tantalum products, please send us your request to for any needs on tantalum products.

Product information:

Customer information: